Loading arms offer a vital solution for the safe and efficient movement of cargoes between vessels and shore-based infrastructure at marine terminals. Such sophisticated systems combine a series of elements, including articulated structures, mechanisms, and monitoring features to provide a seamless and secure procedure.

Diverse types of loading arms are available to suit the specific requirements of different liquids, such as sensitive materials or corrosive substances.

Cutting-edge loading arm technologies often incorporate control systems to enhance efficiency, consistency, and safety.

Improving LNG Loading Arm Operations

Efficient and reliable operations are paramount in the liquefied natural gas (LNG) sector. Loading arms play a critical role in transferring LNG between vessels and shore facilities. To optimize loading arm efficiency, it's essential to implement robust maintenance programs. Regular inspections, component replacements, and lubrication can help prevent unforeseen downtime and ensure safe workflows.

- Moreover, utilizing advanced technologies, such as automated loading systems and real-time monitoring tools, can significantly boost safety and efficiency.

- Education programs for operators are crucial to encourage best practices and limit the risk of accidents.

Ultimately, a comprehensive approach that unifies preventative upkeep, technology developments, and well-trained personnel is vital for optimizing LNG loading arm functions.

Safe and Efficient Transfer of Liquids via Marine Loading Arms

Efficiently transferring bulk liquids between vessels and shore facilities is a vital aspect of global trade. Marine loading arms play a crucial role in this process, providing a safe and reliable method for connecting pipelines or tanks to ships. A well-designed loading arm system comprises specialized equipment such gantry automation, as articulated hoses, swivel joints, and automation mechanisms to ensure smooth fluid transfer while minimizing the risk of spills or leaks.

These arms are constructed from durable materials capable of withstanding harsh marine environments and the dynamic forces involved in loading and unloading operations. Safety features such as pressure relief valves, emergency shut-off mechanisms, and grounding systems further enhance protection against potential hazards.

Regular maintenance and inspection are essential for ensuring the performance and lifespan of marine loading arms. By adhering to industry best practices and implementing robust safety protocols, operators can contribute to a secure and efficient transfer process, protecting both personnel and the environment.

Bottom Loading Arm Systems: Industry-Leading Performance

When it comes to transferring liquids seamlessly and effectively, bottom loading arm systems stand as the gold standard. These robust and versatile systems are designed to deliver superior results in a variety of settings. From fuel terminals to chemical plants, bottom loading arms provide a safe and controlled means of dispensing quantities with minimal downtime and maintenance.

- Key features of bottom loading arm systems include:

- Robust engineering to withstand demanding operating conditions.

- Reliable valve technology for leakproof operation.

- Redundant safety systems to ensure personnel safety.

- Intuitive controls for ease of use and productivity improvement.

By implementing bottom loading arm systems, businesses can optimize their processes while adhering to the highest safety standards.

Next-Gen Loading Arms: Towards Smarter Operations

The loading arms industry is steadily evolving to meet the demands of a dynamic global market. A key area of focus is innovation in transfer systems. This commitment to optimization promises to streamline loading procedures, resulting in improved productivity and a safer work environment.

- High-performance alloys are being integrated to enhance loading arms, making them robust to wear and tear.

- Automation is playing a pivotal role of loading arms. Real-time monitoring are enhancing safety, leading to optimized loading processes.

- Wireless connectivity are becoming increasingly popular, allowing for increased flexibility in confined spaces.

Tailored Loading Arm Solutions for Diverse Industries

In today's dynamic market, sectors demand loading arm solutions that are as specific as their operational needs. From the demanding environment of oil and gas to the stringent requirements of chemical handling, finding the perfect loading arm is crucial for productivity. Our company specializes in designing personalized loading arms that meet the specific challenges faced by each industry.

- Our experts understand that every sector has its own set of demands.

- As a result, we work closely with our clients to assess their exact needs and craft loading arm solutions that optimize performance and safety.

- No matter the application, you can count on us to provide a reliable solution that stands up to the rigors of industrial use.

Jonathan Lipnicki Then & Now!

Jonathan Lipnicki Then & Now! Michelle Pfeiffer Then & Now!

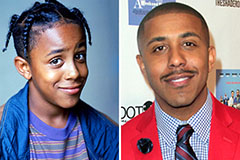

Michelle Pfeiffer Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Erik von Detten Then & Now!

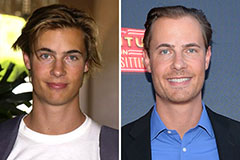

Erik von Detten Then & Now! Shannon Elizabeth Then & Now!

Shannon Elizabeth Then & Now!